MEMBRANE BIOREACTOR

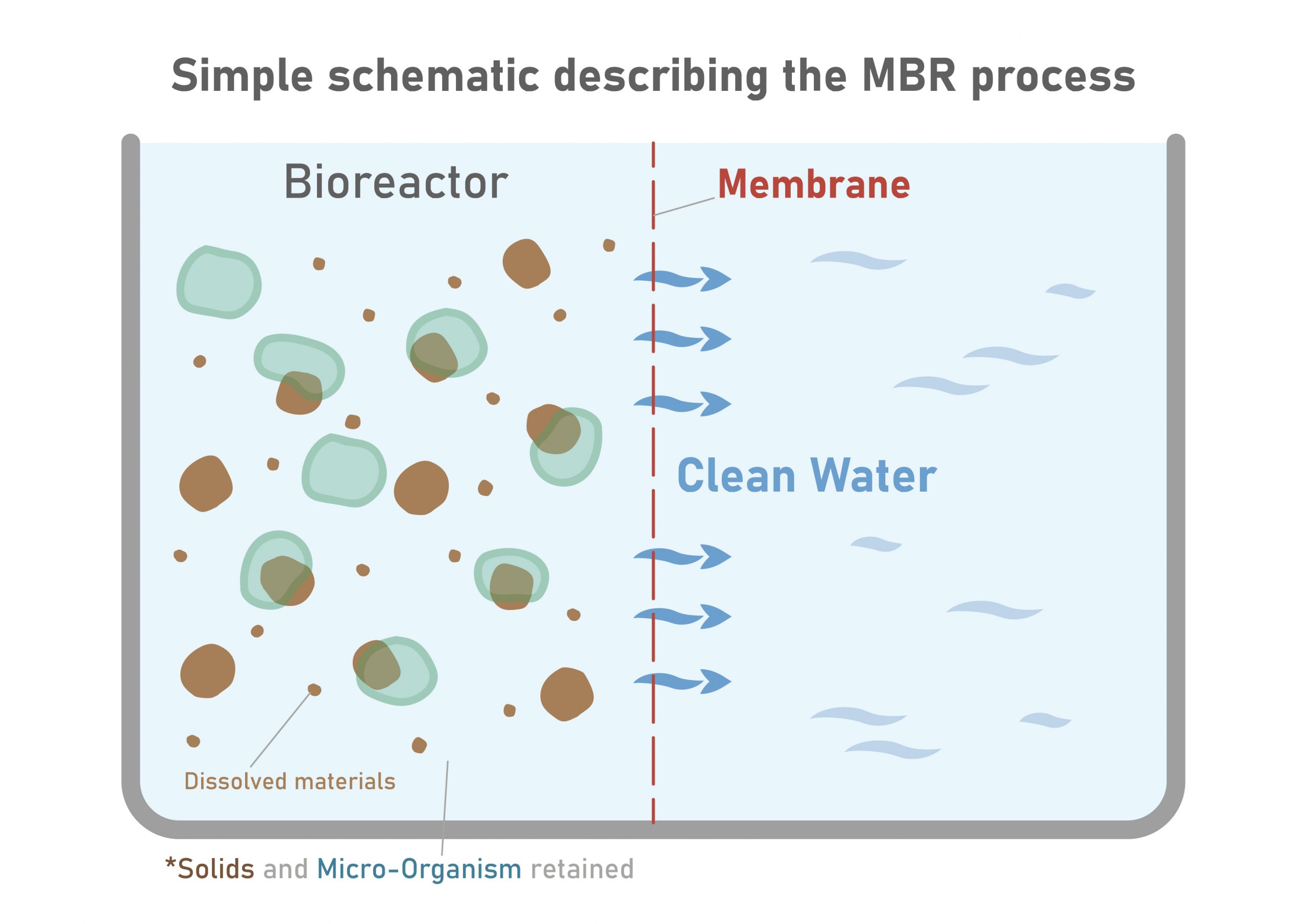

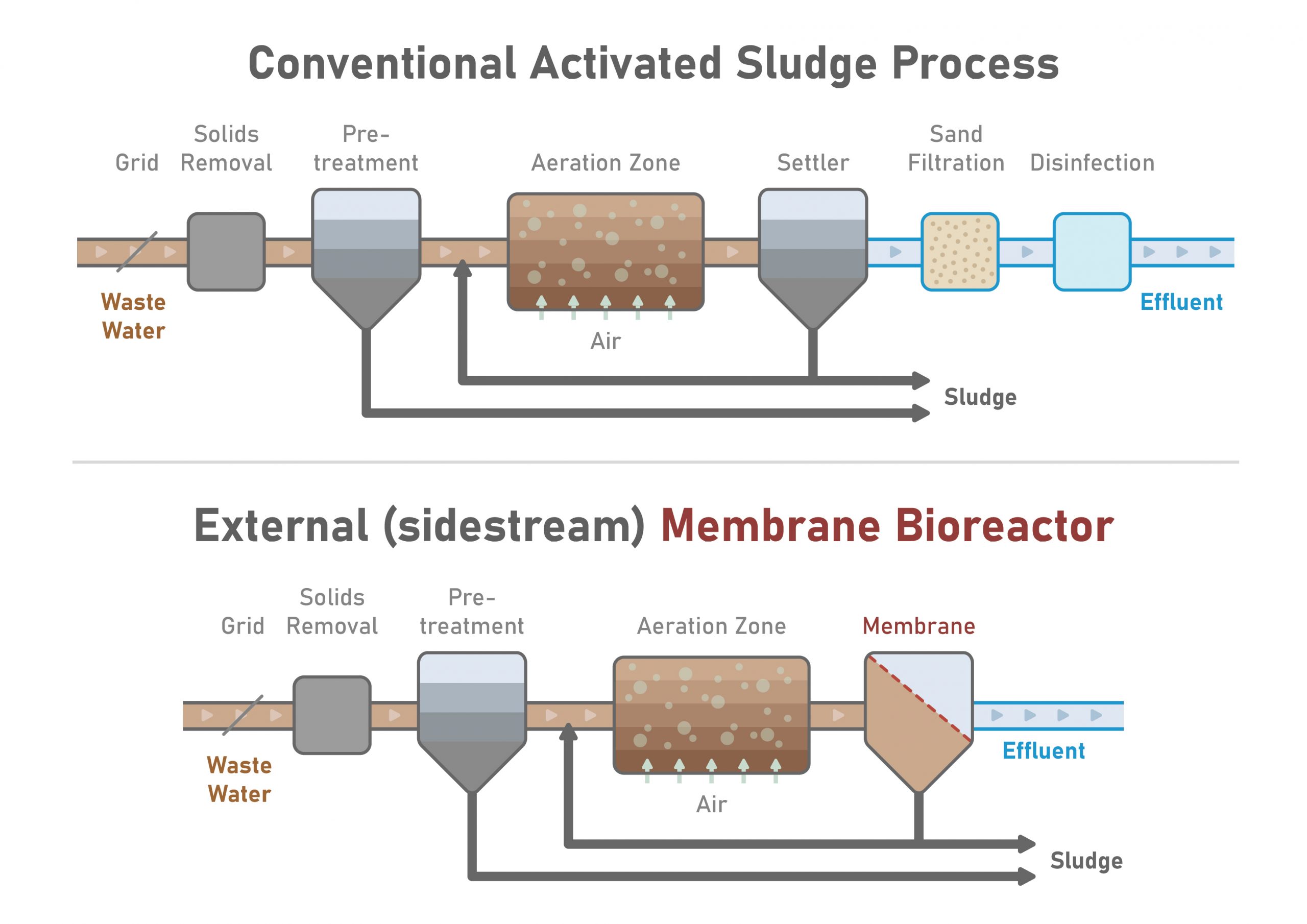

A membrane bioreactor (MBR) combines membrane processes like microfiltration and ultrafiltration along with a suspended growth bioreactor in order to treat industrial and municipal wastewater. It integrates a semi-permeable membrane with a biological process and is now widely used for wastewater treatment.

Membrane bioreactors are a new and innovative way of dealing with all types of wastewater.

ADVANTAGES

- High effluent quality (effective retention of solids and bacteria)

- Smart module design (less braiding and sludge depositions)

- Backflushable module based on flat sheet membranes

- Small footprint (high packing density)

- Reduced energy demand

- Unique membrane laminate with self healing effect

- Optimized oxygen transfer (fine bubble aeration)

Secondary clarifiers and tertiary filtration processes are eliminated, thereby reducing plant footprint. In certain instances, footprint can be further reduced because other process units such as digesters or Ultraviolet disinfection can also be eliminated/ minimised (dependent upon governing regulations). It can be designed to prolong sludge age, hence lower sludge production, high effluent quality and high loading rate capability.

DISADVANTAGES

- High operation and capital costs (membranes)

- Membrane complexity and fouling

- Energy costs

PRODUCT LIST

Biocel

- Biocel MBR

- Biocel XL-2

- Biocel L-2

- Biocel 416

- Biocel 208

- Biocel 104

- Biocel 52

- Biocel XY

PRODUCT LIST

Memstar

- MUSA-SS-TECH-18006.110

PRODUCT LIST

FLAX

- FLAX LMBR-20

- FLAX SLMBR-20

- FLAX SLMBR-25

- FLAX SLMBR-30