CARTRIDGE FILTER & BAG FILTER

Both bag and cartridge style filters offer you removable media and collection of a discrete phase of matter existing in a dispersed or colloidal state in suspension. The decision should be based on the application because each type of media has its advantages and disadvantages.

CARTRIDGE FILTER

Cartridge filters capture solid contaminants on the outer surfaces of the filter media.

These cartridge filters can be used for a wide range of applications where sub-micron filtration is needed. These include pharmaceutical applications as well as those in which ultra-pure water filtration is required: beverage and food production facilities, chemical and paint plants, as pre-treatment for reverse osmosis system / ultrafiltration system / water purification technologies.

Cartridge filters materials in Polypropylene, Polyethylene and PVDF depending on application, temperature, medium etc. All lengths are available in executions of 1 till 120 filter cartridges.

Special customer wishes can be taken into account. The filter housings are available for all possible filter adaptors as DOE, C2, C3, C7 and C8.

ADVANTAGES

- Different kind of plastics for practical all applications

- Position of inlet and/or outlet can be changed

- Standard operating pressure 6 and 10 bar

- In accordance with the PED standards

- Can be CE marked

TECHNICAL DETAIL

| Material | PP, PE & PVDF |

| O – Ring | FTP, EPDM, PTFE Coated |

| Cartridge Length | 10″ to 60″ |

| No. of Cartridges | 1 to 120 pcs |

| Adaptor | DOE, C0, C2, C3, C7, C8 |

| Connection | Flens ANSI/DIN, BSP/NPT (M/F) |

| Pressure at 40°C | 6 or 10 bar |

| Max. Temperature | PP (60°C) PE (50°C) PVDF (90°C) |

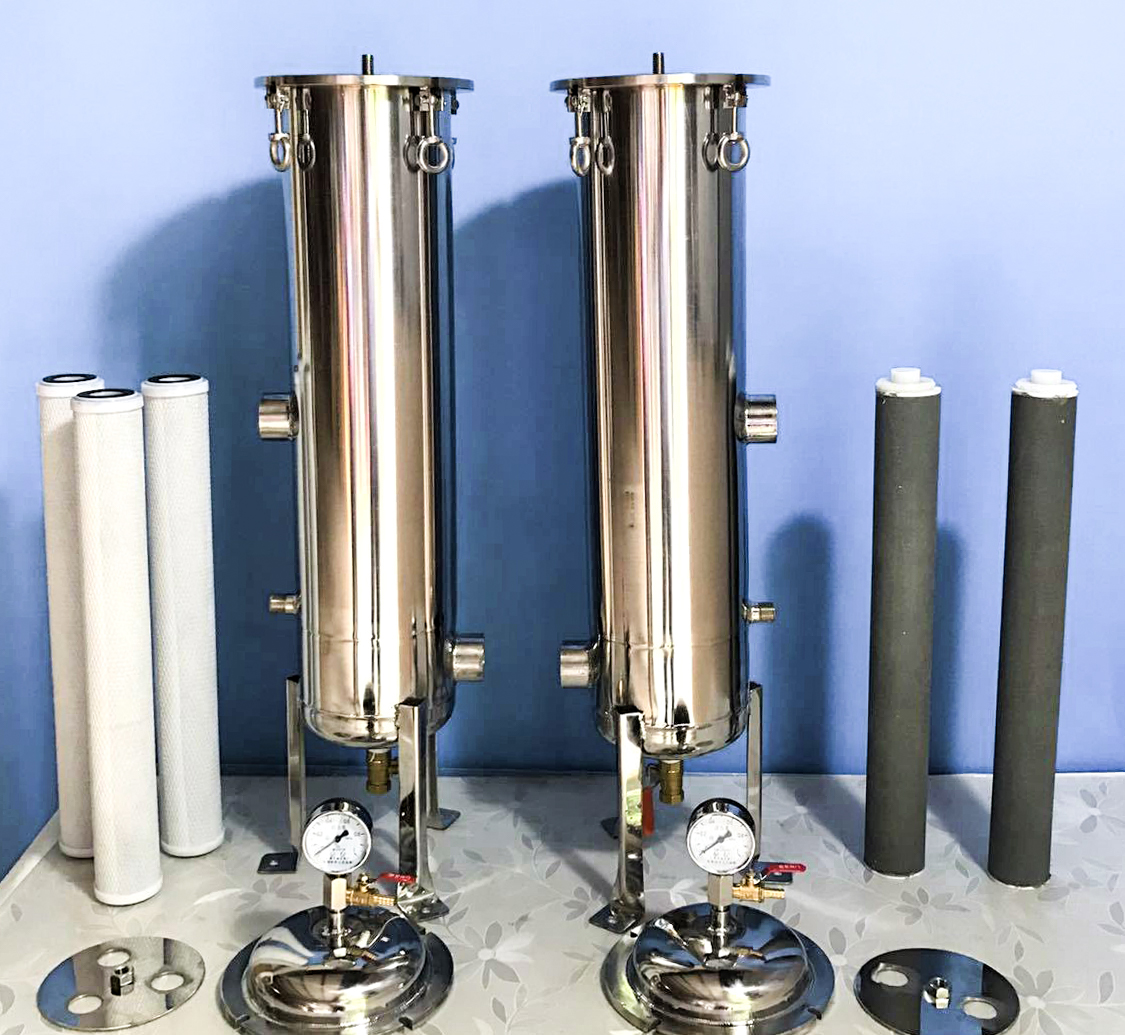

STAINLESS STEEL CARTRIDGE FILTER HOUSING

Stainless steel housings are used in various industries such as water treatment, chemistry, pharmaceutical and food and beverage.

SURFACE TREATMENT HOUSING

- Industrial execution

- Sandblasted

- Electropolished

- Eachined polished

MATERIAL

- AISI 304

- AISI 316

- AISI 316L

- Hastelloy

COATING

- Halar

- PP

- ETFE

- PVDF

- PFA

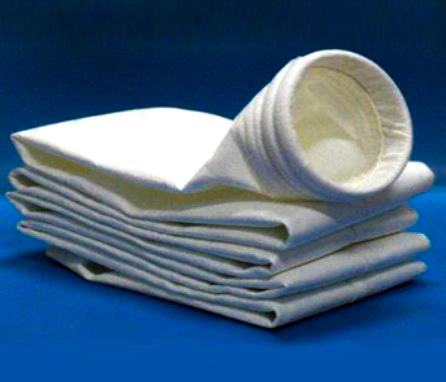

BAG FILTER

Bag filters are often the best choice for many industrial applications. Bag filters use a wide range of filtration media based on the application such as activated carbon, needle felt, and nylon monofilament mesh.

Bag filters operate by trapping waste solids inside the bag and are considered to be a relatively low-cost form of industrial filtration. However, bag filters have a smaller surface area than most cartridge filters. The low overall operating cost makes bag filters an excellent choice for small batch operations where the cost of a self-cleaning system would not be justified.

Along with this, small operations will not have a high bag replacement frequency leading to lower disposal costs.

Bag filtration systems tend to produce less solid waste than cartridge filters, making them an excellent choice for applications where the user wants to minimize their volume of waste.

ADVANTAGES

- The filter housings are suitable for all standard available filter bags

- Different kind of plastics for practical all applications

- Position of inlet and/or outlet can be changed

- Standard operating pressure 6 and 10 bar

- In accordance with the PED standards

- Can be CE marked

The standard sizes 1, 2, 3 and 4 or a customer specified size can be combined to multiple units. Optional are multi bag housings. The maximum available size is 14 filter bags size 2 in one housing. Special customer wishes can be taken into account. The large choice in filter bags as to material and filter rating makes this a cheap solution for many applications. Strainers are available in various executions and capacities suitable as pre-filtration for cooling water with removable basket for easy cleaning perforation (starting with 3 mm).

TECHNICAL DETAIL

| Material | PP, PE & PVDF |

| O – Ring | FTP, EPDM, PTFE Coated |

| Standard Sizes | 1, 2, 3, 4 |

| Baskets | 1 to 14 pcs |

| Connection | Flens ANSI/DIN, BSP/NPT (M/F) |

| Pressure at 40°C | 6 or 10 bar |

| Max. Temperature | PP (60°C) PE (50°C) PVDF (90°C) |

FILTER ELEMENT

Pleated

Pleated cartridge filter element options: standard range, high flow elements and special material specification.

MATERIAL

- PP

- Glassfibre

- PES

- Nylon

- Hydrophobic PTFE

- Hydrophilic PTFE

- Hydrophobic PVDF

- Hydrophilic PVDF

ADVANTAGE

- Large choice of filter materials

- Good price quality ratio

- High flow large dirt holding capacity

- Available with various connections

- Possibility to make custom made cartridges

Filter Bag

HUI supplies filter bags of excellent quality fitting all standard housings. Filterbags are available in traditional stitched or fully welded execution. By using selective materials HUI filterbags belong to the best available. All filterbags are silicon free and food grade approved

ADVANTAGE

- All materials are in conformity with the FDA 21 CFR 177.1520 standard

- All materials comply with the EC 10/2011 standard

- Special sizes possible

- Extensive material choice

TECHNICAL DETAIL

| Material Needlefelt | Polyester (PE) Polypropylene (PO) Polytetrafluorethene (PTFE) Aramide (AF) Nylon (NF) Nomex (N) Ryton (R) |

| Material Mesh | Polyester (PEMO) Polypropylene (PPMO) Nylon (NMO) |

| Micron Rating | 0.5 to 2,000 micron (depending on type of material) |

| Ring | Tinned Steal AISI Polypropylene Sentinel Polyester Sentinel Santroprene Sentinel Polyloc |

| Max. Temperature | Polypropylene (90°C) Nylon (110°C) Polyester (140°C) PTFE (250°C) |

Meltblown Filter Cartridge

Meltblown made of thermally bonded microfibers. The three dimensional sterioscopics structure results in a high efficiency filter cartridge. The three layer construction guarantees an exceptional high dirt capacity.

ADVANTAGE

- All materials are in conformity with the FDA 21 CFR 177.1520 standard

- All materials comply with the EC 10/2011 standard

- 3 layers structure

- Cheap and simple solution for many applications

- Own production so flexible in delivery

- Higher temperature possible by using a support core (80°C)

TECHNICAL DETAIL

| Material | PP |

| Diameter | 60 to 110 mm |

| Cartridge Length | 5″ to 60″ |

| Selectivity | 0.5 to 150 micron |

| Connection | DOE, C2, C3, C7, C8 |

| Max. Temperature |

55°C |

Wound Filter Cartridge

On the most up to date electronic machines we manufacture wound filter cartridges in various materials and with choice of various core possibilities. The diamond shape openings become smaller towards the core and guarantee a true depth filtration and large dirt holding capacity.

ADVANTAGE

- All materials are in conformity with the FDA 21 CFR 177.1520 standard

- All materials comply with the EC 10/2011 standard

- Cheap and simple solution for many applications

- Own production so flexible in delivery

TECHNICAL DETAIL

| Material | PP, Cotton, Polyester & Nylon |

| Core | PP, AISI 304, AISI 316 |

| Cartridge Length | 9¾” to 60″ |

| Selectivity | 0.5 to 150 micron |

| Connection | DOE, C2, C3, C7, C8 |

| Max. Temperature | 80°C till 120°C |