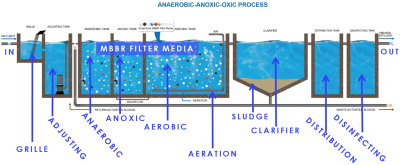

MOVING BED BIOFILM REACTOR

MEDIA FILTER

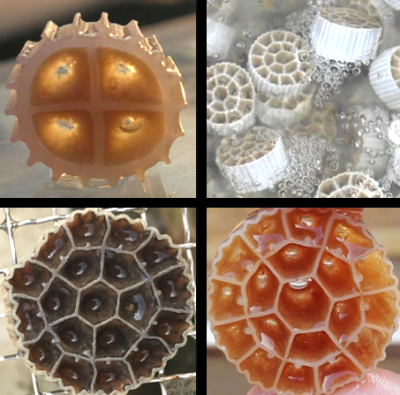

Moving Bed Biofilm Reactor (MBBR) filter media is a novel biologically active carrier. It adopts scientific formula, depending on the nature of water. It blends a variety of beneficial microorganisms which grow quickly attached to trace elements in polymer materials through a special process modification and constructed with more than large surface area whose characteristics are hydrophilic, high biological activity, biofilm fast, good effect and good impact resistance.

HOW DOES MBBR MEDIA FILTER WORK?

The MBBR process utilizes floating plastic carriers (media) within the aeration tank to increase the amount of microorganisms available to treat the wastewater. The microorganisms consume organic material. The media provides increased surface area for the biological microorganisms to attach to and grow in the aeration tanks. The increased surface area reduces the footprint of the tanks required to treat the wastewater. The media is continuously agitated by bubbles from the aeration system that adds oxygen at the bottom of the first compartment of the aeration tank. The microorganisms consume organic material. When compared to conventional secondary treatment it provides superior efficiency and value.

APPLICATION

- Pulp and Paper Industry

- Food and Drink

- Coke and Steel Mill

- Sewage Treatment Plant

- Waste Water Treatment

- Water Treatment

- Waste Water Treatment Plant

- Sewage Treatment

- SBR Sludge Process

- RAS

- Dairy Industry

- Beverage Factory

- Automobile Industry

- Chemical Industry

- Food Waste Water

- Chemical Waster

- Domestic Sewage

- Aeration System

- IFAS Solution

- Spray Tower

- Purification Tower

- Aquaculture and Koi Ponds

- Integrated Container A2O

- Process with Small Footprint

- Printing and Dyeing Waste Water

- Waste Water Treatment System

- Municipal Waste Water Treatment

- Nitrogen Removal from Waste Water

- Industrial Water Treatment

- Municipal Sewage

- Recirculating Aquacultrue System

- Plating and Finishing Treatment Plant

HIGH BIO-ACTIVITY AND

SHORT BIO-FILM TIME

Microorganism starts to grow and attach on bio media within 7 to 20 days under stable system.

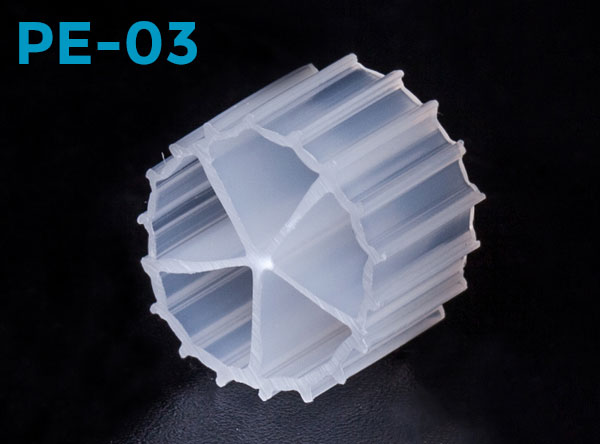

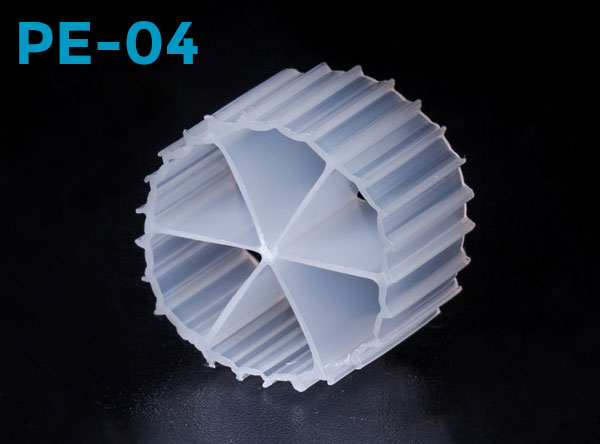

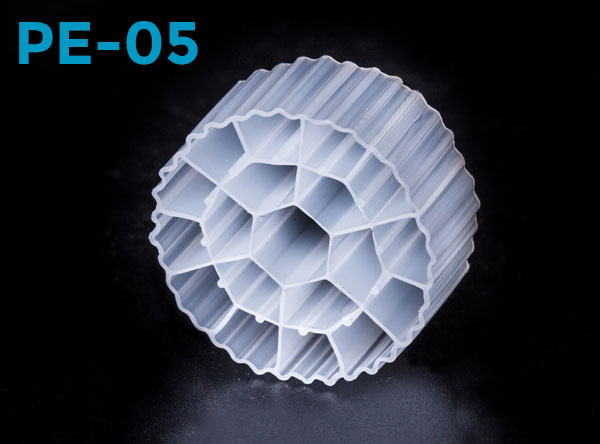

SHAPE

It depends on the good structure and shape to grow more biological membrane. Excellent shape can provide better protected surface area and protect the biological membrane grow.

ADVANTAGES

- Less residual sludge

- Long service life more than 15 years

- High bio-activity and bio-film short time

- High hydrophilicity and excellent adhesion to surfaces

- High bio-activity and bio-film short timex

- Rebuild-free, easy to upgrade or expand

- High impact resistance and stable operation

- High volume load, high filling rate and less land occupation

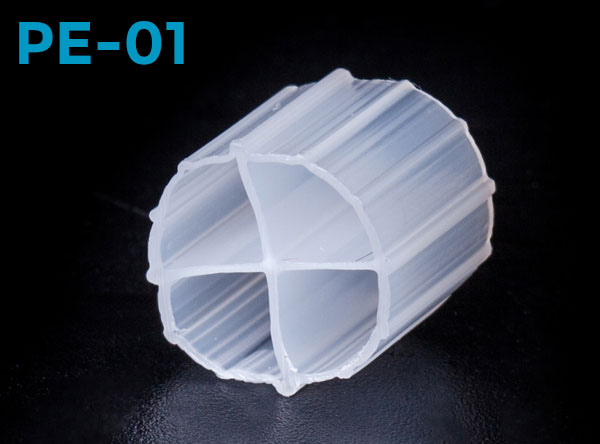

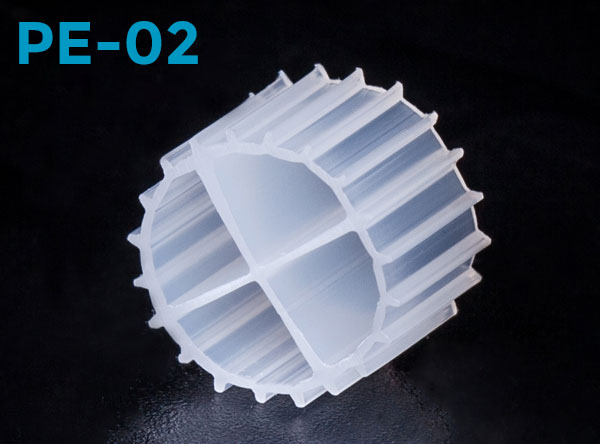

VARIANT

It depends on the good structure and shape to grow more biological membrane. Excellent shape can provide better protected surface area and protect the biological membrane grow.

VARIANT TABLE

| Type | Dimension (diameter x thickness) | Density | Surface Area | Packing Number | Dosing Ratio | Life Span | Nutrification Efficiency | Material |

| PE-01 | Φ 12*9 mm | 0. 94 – 0. 97 g/cm³ | >800 m2/m3 | >630,000 pcs/m³ | 15% -70% | >15 years | 400 – 1,200 gNH4 -N/m³.d | HDPE |

| PE-02 | φ11*7 mm | 0. 94 – 0. 97 g/cm³ | >900 m2/m3 | >930,000 pcs/m³ | 15% -68% | >15 years | 400 – 1,200 gNH4 -N/m³.d | HDPE |

| PE-03 | φ10*7 mm | 0. 94 – 0. 97 g/cm³ | >1000 m2/m3 | >990000 pcs/m³ | 15%-70% | >15 years | 400 – 1,200 gNH4 -N/m³.d | HDPE |

| PE-04 | φ16*10 mm | 0. 94 – 0. 97 g/cm³ | >800 m2/m3 | >260000 pcs/m³ | 15%-67% | >15 years | 400 – 1,200 gNH4 -N/m³.d | HDPE |

| PE-05 | φ25*10 mm | 0. 94 – 0. 97 g/cm³ | >600 m2/m3 | >118000 pcs/m³ | 15%-65% | >15 years | 400 – 1,200 gNH4 – N/m³.d | HDPE |